with Industry-leading AI & Automation

At Synergy & Brighten, we specialize in three core areas–proprietary AI image processing, automation equipment manufacturing, and industrial sales. These pillars enable us to provide a diverse range of solutions, including AI-powered visual inspection, 3D picking systems, and robot staffing services.

AI Image Processing Software

Our AI software analyzes the products and learns by itself, enabling application across a wide range of scenarios. Leveraging our in-house expertise in component manufacturing, we deliver user-centric solutions tailored to your needs.

From auto-visual inspection to classification, we address diverse industry requirements.

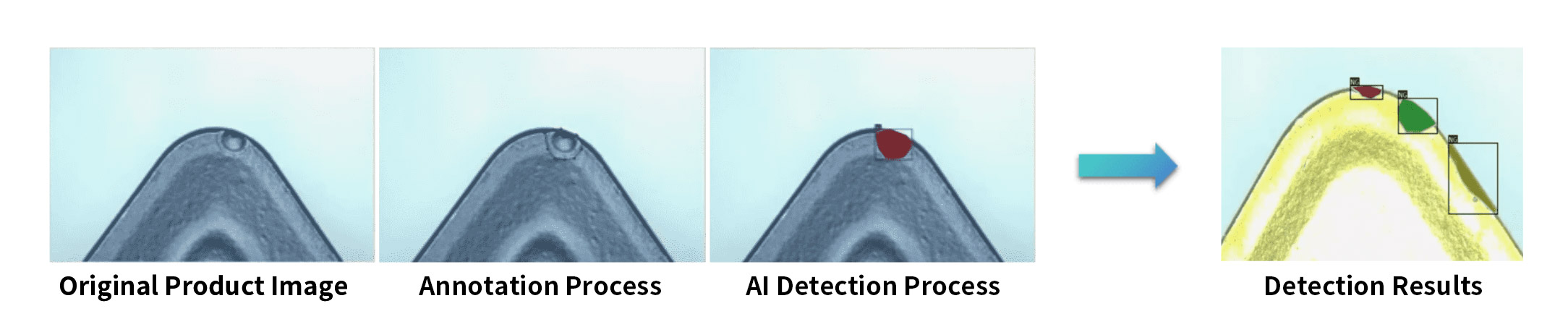

What is AI Image Processing?

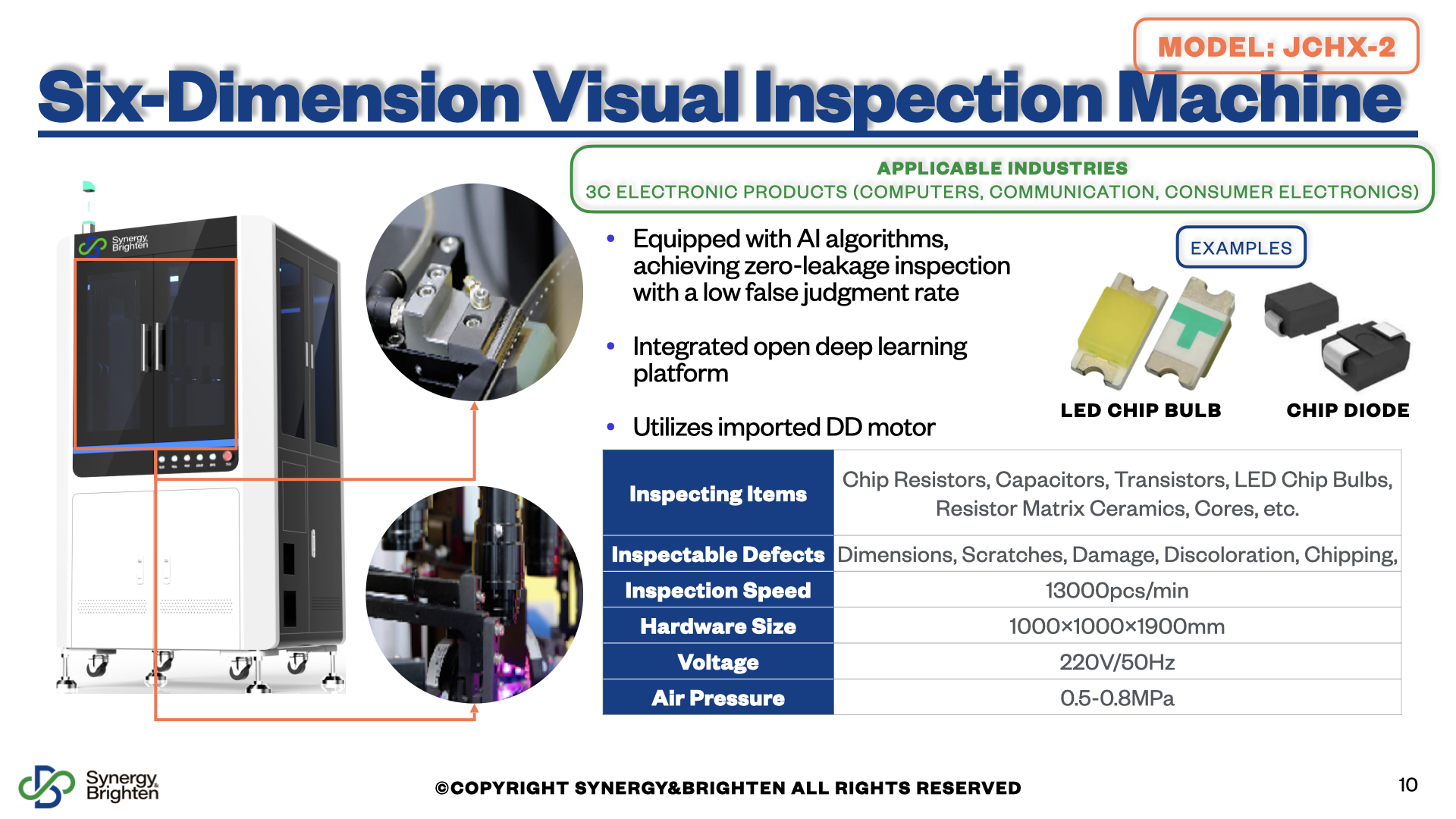

AI image processing is a technology that utilizes artificial intelligence (AI) to automatically extract and analyze valuable information from images and videos. In the manufacturing industry, this enables high-speed, high-precision quality inspection and defect detection, performing at a level equal to or even surpassing human visual inspection. Compared to traditional manual inspection, AI image processing enhances efficiency, accuracy, and cost reduction, while also reducing the workload on production sites. At Synergy & Brighten, we take a hybrid approach, combining the strengths of AI-driven analysis and pattern matching techniques to deliver the most precise and adaptable inspection solutions. This ensures that each system is tailored to our clients' unique needs, providing both high accuracy and reliability, even in complex production environments.Pattern Matching Processing Method

Conventional image processing relies on pre-set templates, such as detecting parts by matching their shape to a predefined pattern. While this approach is simple and fast, it struggles with deformations, variations in viewing angles, or unexpected changes, leading to decreased accuracy.AI-Powered Image Processing Method

AI learns patterns from images and applies that knowledge to classify and detect unknown images with high precision. Unlike traditional methods, AI can adapt to variations in part shapes, different angles, and complex conditions, making it significantly more flexible and reliable in real-world applications.AUTOMATION EQUIPMENT

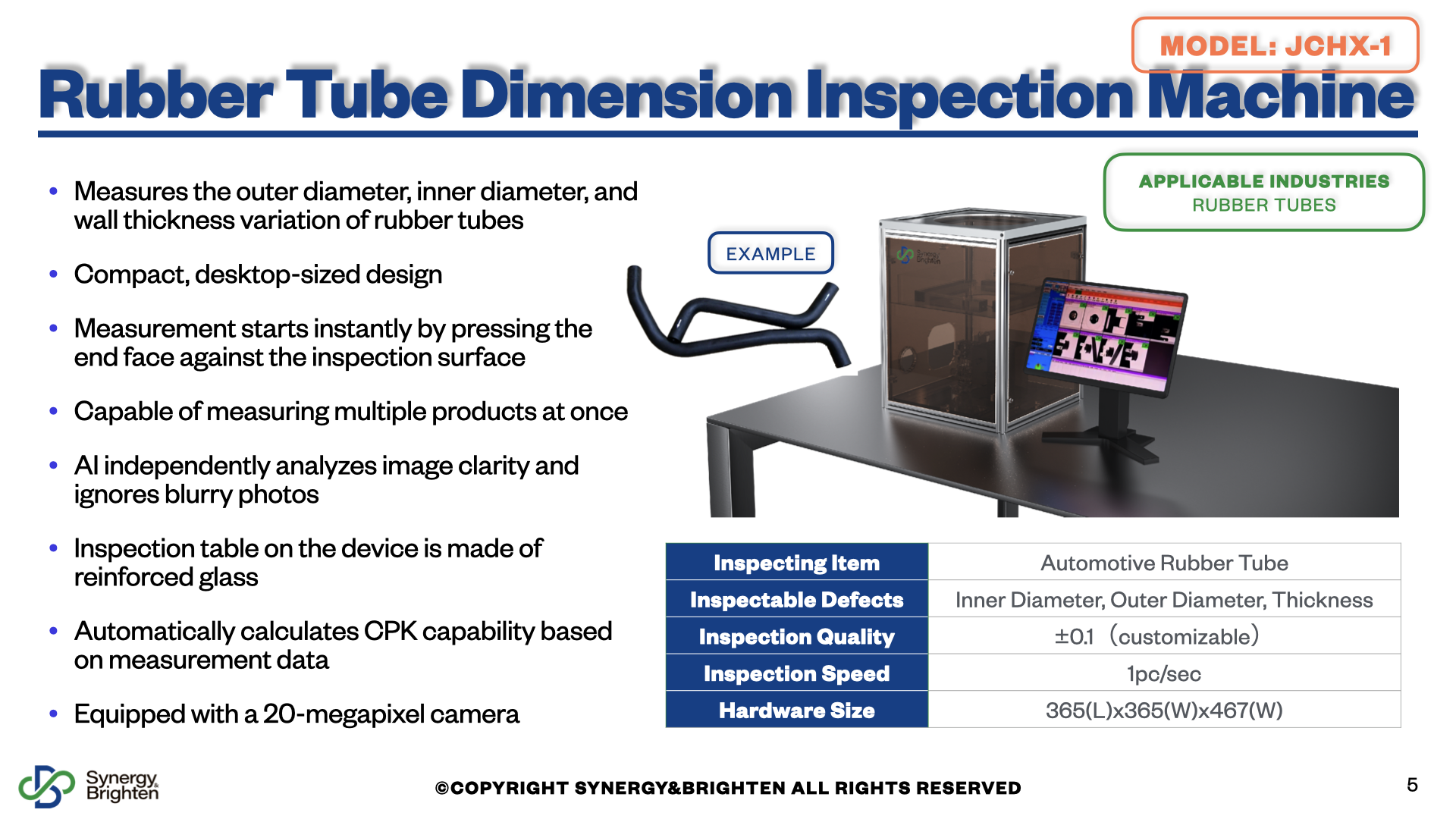

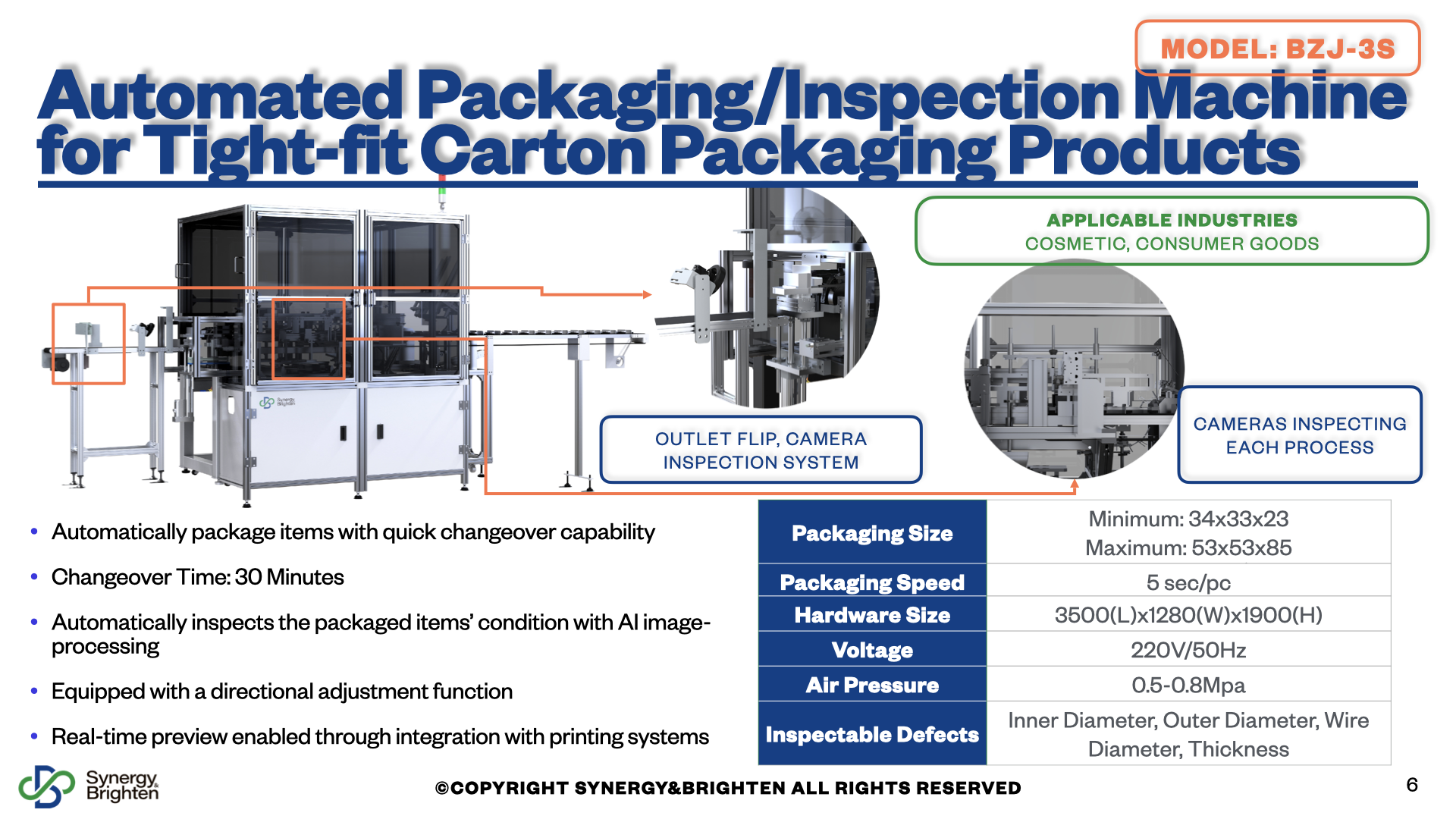

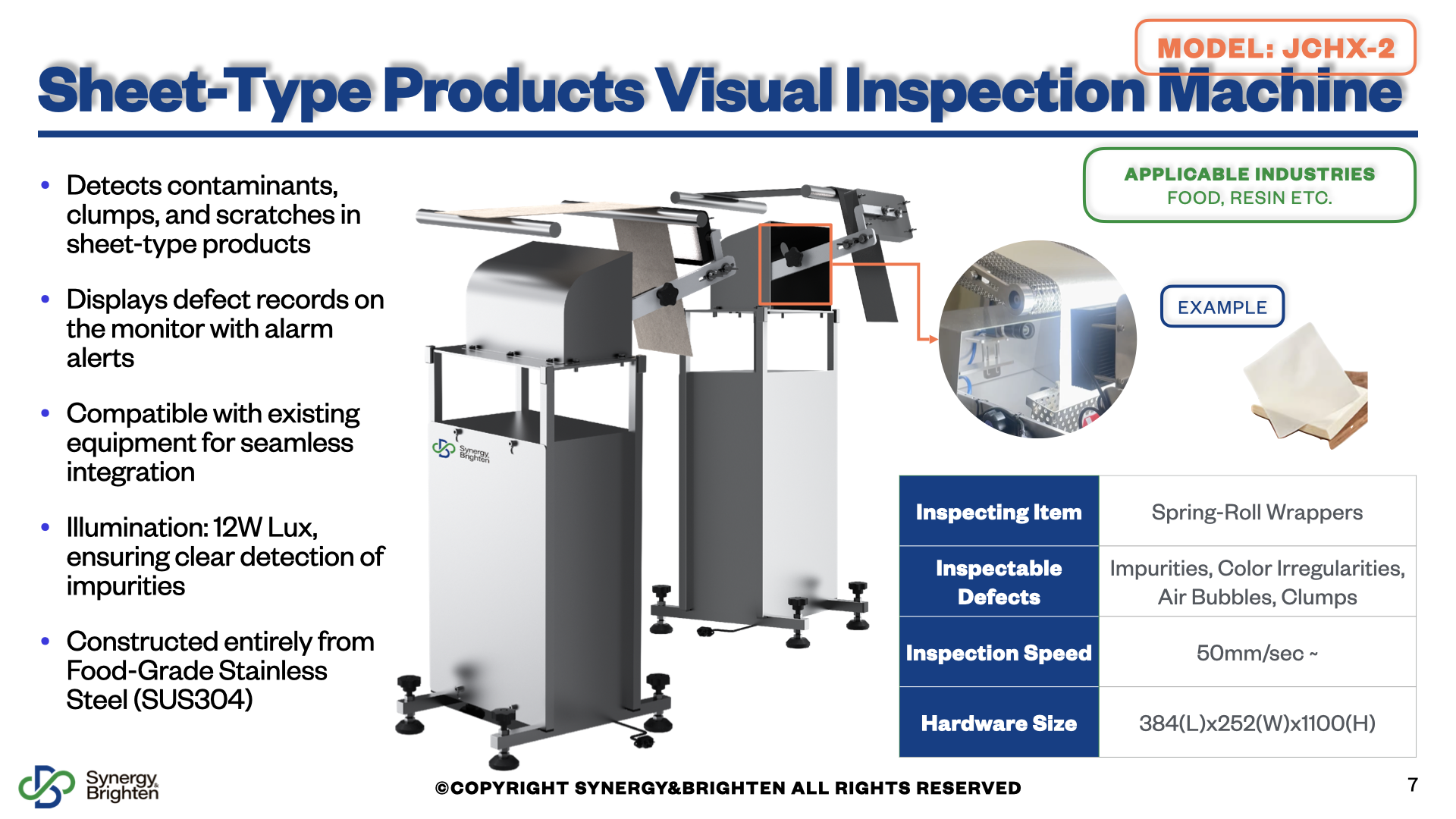

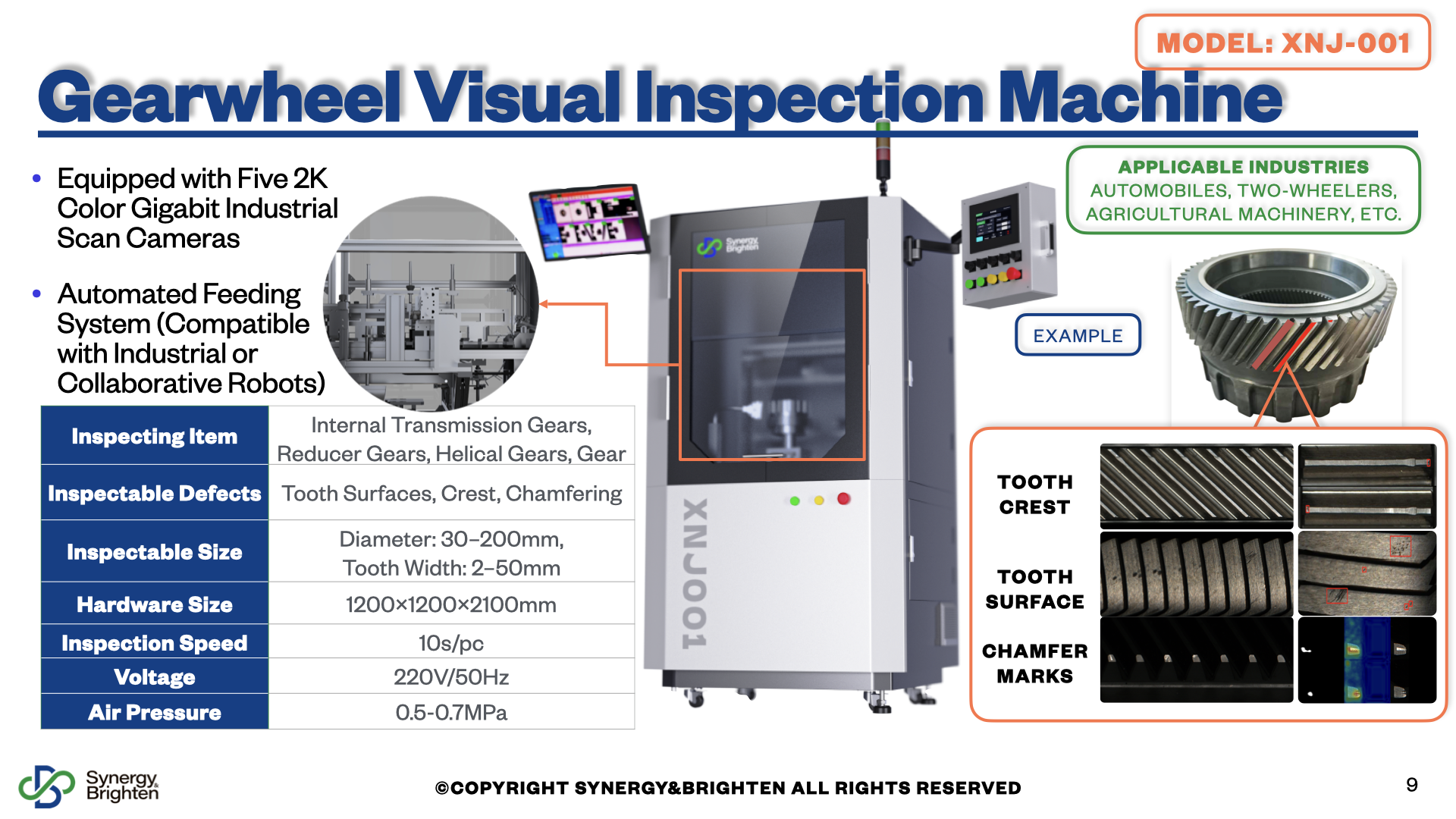

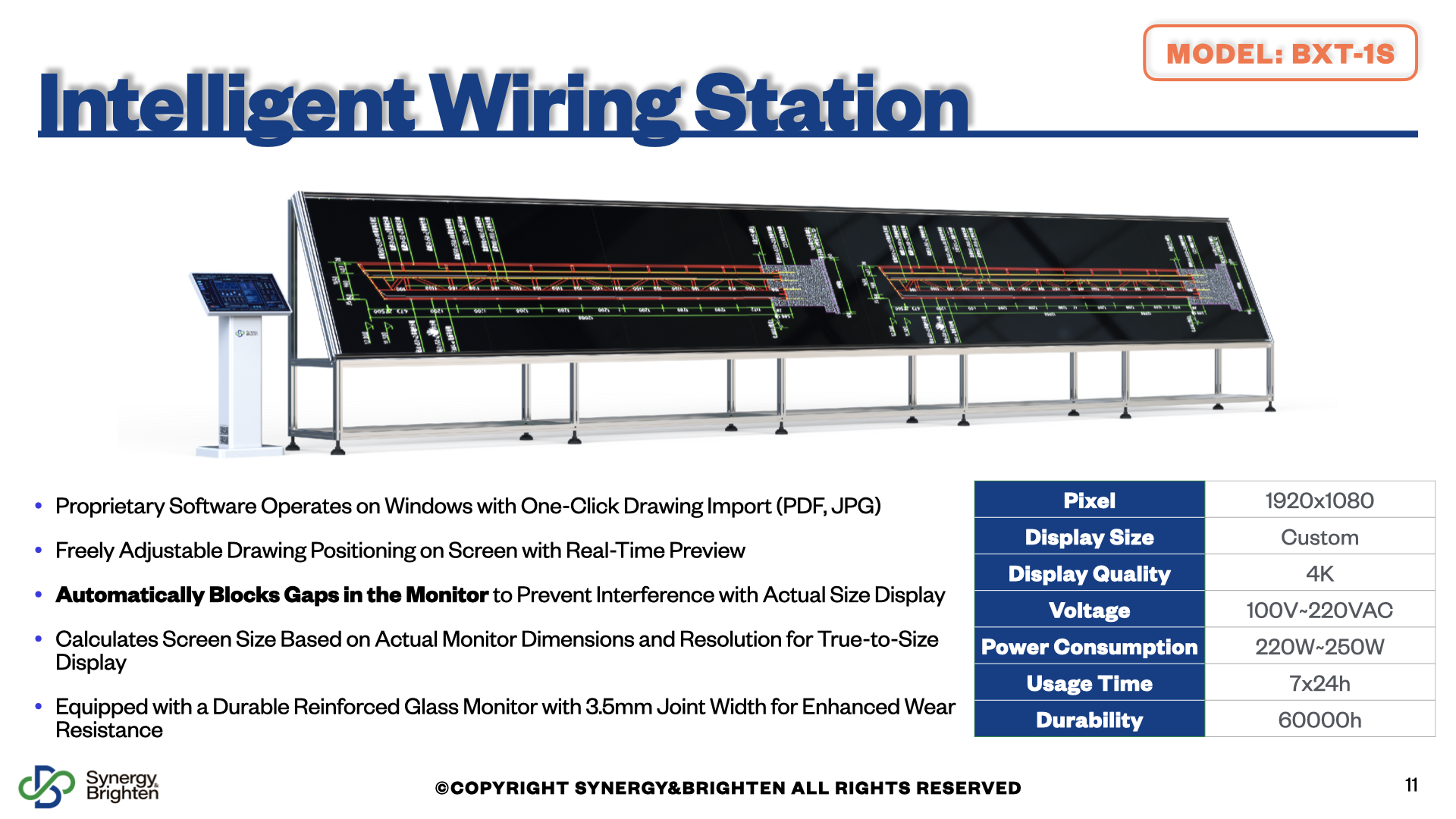

We leverage the manufacturing expertise cultivated within our group companies to deliver cutting-edge equipment that goes beyond customer expectations, tailored to meet their specific needs.

From initial planning to full-scale production, we ensure a seamless experience at every stage, providing stress-free, high-precision, fast, and cost-effective automation and visual inspection solutions, even in highly technical sectors.

INDUSTRIAL PARTS SALES

Synergy group specializes in producing highly technical machined components production that meet strict tolerance requirements.

- Cold Plastic Processing (Cold Forming)

- By using in-house seamless steel tubes as raw materials and optimizing manufacturing processes in China, we have successfully designed a stable and efficient production workflow that significantly reduces forging process steps while maintaining high quality.

- Aluminum Alloy Extrusion

- With our proprietary high-strength aluminum “SYNAL”, we achieve lightweight component production using high-strength extrusion materials. Through grain structure control, its applications in automotive exterior parts continue to grow.

- Cold Pilger Rolling

- Our cold pilger rolling technology enables the production of high-strength, high-precision, non-circular seamless copper tubes, allowing for hollow, thin-walled component design, ideal for advanced manufacturing applications.

AI VISUAL INSPECTION SYSTEM

A next-gen automated inspection solution for manufacturers aiming for superior quality assurance, combining the world’s most advanced AI image processing software with our cutting-edge automation systems.

By effectively integrating AI and robotics, we achieve significant cost reduction and operational efficiency, delivering both enhanced productivity and improved quality–simultaneously.

| Industry | Defects & Issues |

|---|---|

| Metal | Cracks, chips, burrs, dimensional misalignment, deformation, rust, cavities,bubbles, dents, etc. |

| Food | Tears, stains, burns, dents, scratches, foreign objects, printing errors,contamination, etc. |

| Plastics | Silver streaks, scratches, stains, streaks, discoloration, bubbles, etc. |

| Electronics | Contamination, foreign object adhesion, short circuits, disconnections, solder deficiencies, etc. |

| CPG | Presence or absence of printing, smudging, misprints, torn or misaligned labels,etc. |

| Medical | Liquid level, sealing integrity, content volume, misaligned or damaged labels,printing errors, etc. |

| Sheet Molding | Pinholes, lens defects, gels, bubbles, cracks, fractures, etc. |

3D Picking

A 3D Picking AI Robot is an advanced robotic system designed to automate part handling and picking tasks in manufacturing environments by leveraging AI (Artificial Intelligence) and 3D image recognition technology. By analyzing 3D data captured from cameras and sensors, the robot accurately detects object shape, size, and position, determining the optimal way to pick and transport items to designated locations with precision.

- Adaptability to Irregular (Random) Arrangements

- In manufacturing environments, parts are often stacked or placed randomly. The 3D picking robot utilizes a 3D camera to recognize spatial depth, allowing it to detect and grasp objects even from angles that are not visually accessible.

- High-Precision Picking Operations

- Powered by AI technology, the robot ensures consistent accuracy in picking tasks without misgripping or dropping objects. This is particularly beneficial for handling precision instruments and delicate components, where maintaining strict quality control is essential. By reducing inconsistencies, the system also helps minimize defective products.

- Reduced Workload, Lower Risks & Labor Shortage Solution

- By automating manual picking tasks, the robot significantly reduces the burden on workers, enhancing workplace safety and efficiency. In some cases, 24/7 robotic operation can further optimize production lines and increase overall productivity, making it an effective solution for addressing labor shortages.

- Flexible Application Across Industries

- With adjustable settings based on product type and size, the system can be utilized across a wide range of industries, ensuring versatile and scalable automation.

ROBOT STAFFING

Our robots enable fast, risk-free implementation with only installation and custom hand costs upfront, allowing for immediate cost reduction. With the flexibility to cancel anytime, businesses can seamlessly adapt to fluctuating production demands without long-term commitments. Designed for small and mid-sized manufacturers, our subscription-based model helps solve labor shortages and ensures stable production, making automation more accessible and efficient.

with Innovation & Expertise

At Synergy & Brighten, we combine proprietary AI image processing, automation equipment, and industrial component solutions to deliver powerful, future-ready systems. From AI-powered visual inspection and 3D picking to robot staffing services, our integrated offerings are built to solve real-world challenges—boosting efficiency, enhancing quality control, and reducing operational strain. With end-to-end support and customizable systems, we help our clients build smarter, more agile manufacturing environments.

Built for Craftsmen Committed to the Highest Quality Standards

We provide a comprehensive end-to-end service, guiding you from initial consultation and system design to construction, installation, testing, implementation, and post-implementation support. Beyond simply combining necessary components, we tailor each technology to custom specifications that align with your unique operational needs, ensuring a truly optimized solution.

- Low Efficiency & Productivity – Automate visual inspection processes to streamline workflows and enhance operational efficiency

- Labour Shortages – Minimize workforce dependency by automating critical workflows, ensuring stability in production

- Quality Inconsistencies – Reduce human error with AI-driven analysis, eliminating unnecessary waste costs

- Scalability Challenges – Implement flexible AI solutions that adapt to production demands and support business growth

- Complex Inspection Requirements – Detect minute defects and variations with precision AI analysis, ensuring high-quality standards

Designed for Businesses Focused on Maximizing ROI

We offer a robust, results-driven approach, helping businesses maximize their return on investment through strategic consultation, tailored system design, seamless implementation, and ongoing support. Rather than a one-size-fits-all approach, we customize each solution to align with your operational goals, ensuring efficiency, scalability, and long-term value.

Read Success Stories

See how our solutions have transformed businesses across industries.

- Highly Adaptable – Suitable for a wide range of industries, scenarios, and product

- Advanced Detection Capabilities – Our in-house custom AI software identifies even the most challenging defects with precision

- Future-Proof Automation – AI and robotics integration ensures scalable, next-generation manufacturing operations

- Cost-Effective & Scalable – Designed to support businesses of all sizes, our automation solutions deliver efficiency, flexibility, and sustainable ROI growth

- Hybrid Approach for Maximum ROI – Optimized for enterprises seeking both enhanced quality and profitability, our approach goes beyond AI, enabling the labeling and categorization of various inspection items for superior control

Explore Our Products

For more information regarding our AI Technologies and Automation Products.